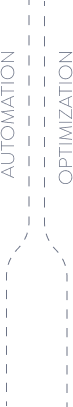

Automation

Optimization

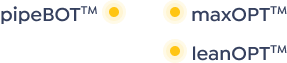

our other solutions

our solutions

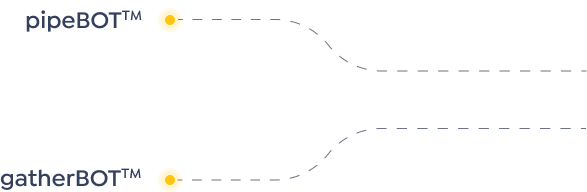

gatherBOTTM

Improves ratability, enabling contract fulfillment for gathering systems

Explore Solutions

gatherBOTTM

Improves ratability, enabling contract fulfillment for gathering systems

Explore Solutions

1

/6

Our Software Deployment Process

Software deployment refers to the process of making a software application available for use. The deployment process includes all the necessary steps to install the software into a live production environment where control room operators can utilize it.

The Control Room of the Future

If you’re looking to apply CruxOCM tech to your specific industry—whether it’s hydro, gas plants, utilities and more—we want to hear from you! Get in touch today to see how CruxOCM can help you build your control room of the future.