Industrial AI is rapidly transforming how industries operate, enabling organizations to unlock new levels of efficiency, safety, and profitability. In its early days back in the 1960s, manufacturers first used AI for robotics and basic automation to handle repetitive tasks like assembly and sorting. Over the decades, advancements in machine learning, computer vision, and the Industrial Internet of Things (IIoT) have dramatically expanded AI’s role, from automating visual inspections to enabling predictive analytics for machine health monitoring. Today, sophisticated AI-driven solutions are indispensable in modern industrial automation and process control.

By amplifying human abilities and providing actionable insights, AI empowers workers and managers alike to make better decisions, reduce cognitive load, and achieve operational excellence. This article explores what industrial AI is, outlines its benefits, delves into its role in automation and midstream oil and gas, offers expert insights on the future, and answers common questions for managers seeking practical, evidence-based guidance.

What Is Industrial AI?

Industrial AI refers to the application of artificial intelligence technologies to industrial operations. Among the most widely used AI technologies are machine learning, advanced analytics, robotics, and computer vision. Unlike general AI, industrial AI is tailored for use cases like process optimization, supply chain management, predictive maintenance, and automated quality control. It thrives on large, complex datasets generated by industrial equipment, sensors, and control systems.

Key functions of industrial AI include:

-

Predictive analytics for maintenance and anomaly detection

-

Real-time process optimization and control

-

Automated visual inspections and defect detection

-

Supply chain and logistics optimization

-

Workflow automation and decision support

One of AI solutions’ core advantages is its adaptability to dynamic process environments. Sophisticated industrial AI reduces manual labor to enhance human capabilities, allowing operators and managers to focus on high-value tasks while AI handles information management and routine decision-making. This evolution is especially relevant as the industry faces increasing complexity, workforce shortages, and the need to improve operational safety and profit margins.

Benefits of Industrial AI for Operations

For companies in the heavy industry, such as oil and gas, industrial AI delivers measurable advantages that directly address core business priorities: reducing costs, increasing revenue, and improving operational safety and stability.

-

Cost Reduction: AI-powered predictive maintenance tools monitor equipment health in real time, enabling companies to anticipate and prevent failures before they occur. This proactive approach minimizes unplanned downtime and extends asset lifespans, resulting in significant savings on repairs and maintenance.

-

Revenue Growth: AI enhances operational efficiency across the value chain, from exploration to refining. In midstream, AI-driven solutions analyze real-time data from pipelines, compressors, and gathering networks to identify bottlenecks, balance flows, enhance asset utilization, and maximize throughput. This dynamic optimization leads to more consistent delivery, fewer product losses, and improved capacity utilization – all of which translate to increased revenue. Additionally, by reducing manual interventions and process variability, AI helps operators meet contractual obligations more reliably and capitalize on market opportunities with greater agility.

-

Operational Safety & Stability: AI continuously monitors critical infrastructure, such as pipelines and processing equipment, to detect anomalies and predict potential safety hazards. Real-time risk modeling and virtual simulations help operators identify and address threats before they escalate, reducing the likelihood of accidents and environmental incidents. AI systems also support regulatory compliance by tracking emissions and operational parameters, further enhancing safety and stability.

-

Informed Decision-Making: By processing vast amounts of operational data and breaking the silos, AI delivers actionable insights that empower operators to make faster, more accurate decisions to benefit the business. This data-driven approach reduces human error, supports strategic planning, and enables rapid response to market fluctuations or operational challenges.

-

Competitive Edge: Early adopters of AI gain a significant advantage by streamlining operations, optimizing supply chains, and adapting quickly to changing market conditions. This agility translates to increased profitability and the ability to capitalize on new opportunities ahead of competitors.

Industrial AI is not just another technological upgrade, but a strategic lever for oil and gas businesses seeking to drive down costs, boost revenue, and ensure safe, stable operations in a volatile energy landscape.

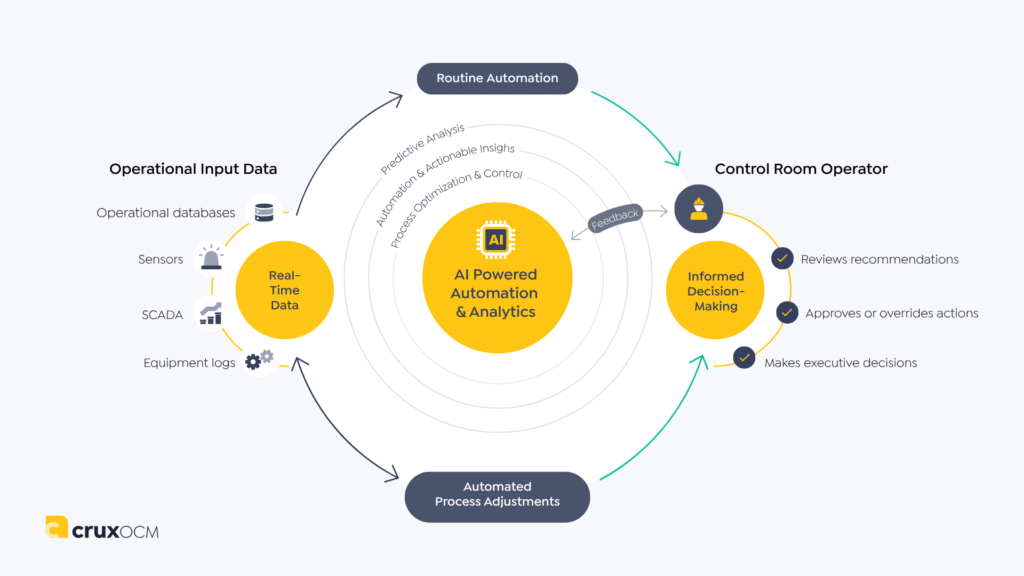

AI in Industrial Automation

Automation stands out as one of the most transformative applications of AI in industrial settings. As the industry has evolved, automation technologies have become increasingly sophisticated, enabling safer and more efficient management of complex and hazardous processes. With the advent of AI, automation has reached a new level of intelligence, driving improved safety, higher profit margins, and a more positive, empowered experience for operators through advanced, intelligent automation. By automating both routine and complex processes, AI significantly reduces cognitive load, stress, and fatigue experienced by operators. This allows frontline workers to focus on high-level decision-making and problem-solving, rather than being bogged down by repetitive manual tasks.

Key Advantages of AI-Powered Automation

-

Real-Time Actionable Insights: AI systems continuously analyze data from sensors, control systems, and operational logs to deliver real-time actionable insights. This enables operators to respond proactively to changing conditions, optimizing performance and preventing issues before they escalate.

-

Automated Process Adjustments: AI-driven automation can make real-time adjustments to process parameters, minimizing human error and reducing operational variability. This leads to more consistent outputs, higher product quality, and fewer safety incidents.

-

Reduced Mental Strain and Enhanced Oversight: With AI handling routine monitoring and adjustments, operators are empowered to oversee more complex systems with less mental strain. This improves job satisfaction and enhances overall workforce performance and retention.

-

Safer, More Supportive Work Environment: AI-powered systems create a safer workplace by automating hazardous or monotonous tasks, allowing personnel to focus on tasks that require human judgment and creativity.

The Power of Autonomous Human-in-the-Loop Software

While fully autonomous systems offer significant benefits, the most effective industrial AI solutions integrate human expertise with advanced automation through human-in-the-loop (HITL) software. These platforms are designed to bridge the best of both worlds: the speed and precision of AI with the contextual understanding and critical thinking of experienced operators. The remarkable efficiency of human-in-the-loop (HITL) software stems from its adaptable approach, where AI rapidly analyzes data and delivers actionable insights to operators. This allows operators to evaluate and respond to situations with greater speed and accuracy than would be possible with purely automated systems or manual control alone.

Key features of human-in-the-loop software:

-

Collaborative Decision-Making: HITL systems allow AI to handle data processing, anomaly detection, and routine control, while operators are alerted to situations that require expert judgment or strategic intervention. This ensures that high-value decisions at critical moments always benefit from human oversight.

-

Learning from Experts: Human-in-the-loop software can learn from operator inputs over time, refining its algorithms and recommendations to better align with real-world best practices and site-specific nuances.

-

Transparency and Trust: By keeping operators in the loop, these systems build trust in AI-driven automation. Operators can review, validate, or override AI recommendations as needed, ensuring that technology remains a tool that amplifies human ability rather than replacing it.

-

Agility in Crisis: In unexpected or emergency situations, HITL platforms ensure that operators retain control, making it possible to quickly adapt to new information or rapidly changing conditions.

AI-powered automation, especially when integrated with autonomous human-in-the-loop software, delivers operational efficiency, safety, and reliability, while empowering operators to make high-value decisions when it matters most. This synergy between advanced technology and human expertise is the key to achieving superior outcomes in modern industrial environments.

AI for Industrial Process Control in Midstream Oil & Gas

The midstream oil and gas sector faces unique operational challenges, including fluctuating throughput, manual set point adjustments, and the need for reliable, safe pipeline operations. Industrial AI addresses these pain points through specialized solutions:

-

Throughput Variability and Manual Adjustments

-

Pain Point: Operators frequently face the challenge of making numerous manual adjustments to maintain consistent throughput and meet the contractual goals.

-

Solution: AI-powered closed-loop gatherBOT™ solution automates the scheduling of gathering system operations, reducing flow and pressure variations by up to 45% and 30%, respectively, and ensuring contractual obligations are met.

-

- Pipeline Safety and Leak Prevention

-

Pain Point: Pipelines are at risk of cracks and leaks due to pressure cycling and aging infrastructure.

-

Solution: AI-powered closed-loop control, such as pipeBOT™, use real-time data and advanced analytics to reduce pressure cycling and prevent failures, enhancing safety and minimizing environmental risks. Deploying pipeBOT™ reduces alarms by 35% and minimizes manual commands by up to 85%.

-

- Throughput Constraint

-

Pain Point: Operational bottlenecks and underutilized pipeline capacity limit throughput potential.

-

Solution: maxOPT™ optimizes nominations and operational parameters to improve operational consistency and maximize throughput by 1-7%.

-

- Inefficient Operations

-

Pain Point: Operational inefficiencies often occur because operators must manage manual setpoint changes and choose the right pump configurations while handling many other complex challenges on the job.

-

Solution: The leanOPT™ solution reduces power consumption and decreases equipment wear to enhance operational safety and reduce costs.

-

-

Power Optimization

-

Pain Point: Energy consumption is a major cost driver in midstream operations.

-

Solution: powerOPT™ leverages AI to optimize energy use, reducing power costs by up to 10% while maintaining operational reliability.

-

By selecting comprehensive AI-powered software solutions like the ones offered by CruxOCM, midstream businesses can achieve a high level of operational autonomy that not only optimizes complex processes but also amplifies the expertise of their workforce. This synergy enables operators to make smarter, faster decisions, significantly reducing manual workload while unlocking substantial business value. Ultimately, this positions midstream companies to enhance efficiency, improve reliability, and secure long-term competitiveness in an evolving energy landscape.

The Future of Industrial AI: Expert Insights

The future of industrial AI is promising, with rapid advancements in generative and predictive AI software enabling even greater operational excellence. According to leading industrial AI providers, the most successful solutions are developed by technology companies with deep domain expertise, a collaborative attitude, and a robust knowledge graph to build innovative solutions guided by customer value.

It is easy to see how data-intensive tasks, such as support and predictive maintenance, are being transformed in the current wave of Industrial AI. What is less obvious is the profound impact that Industrial AI can have on company operations, which are typically characterized by established norms and processes that involve slow-moving, long-term analysis and decision-making. The industry is at the cusp of a major transformation, where winners will be those companies that embrace real-time AI-supported operations. Decisions that used to take a long time to permeate into company operations will be performed in real-time by Industrial AI Agents that can execute deep analysis and thoroughly implement those changes in the company operations as an immediate response to market and world events. Slow moving companies will be left behind those that transform into AI-supported agile organizations.

Carlos Garcia-Alvarado, VP of Engineering at CruxOCM

As AI capabilities expand, operators and managers can expect even more intuitive, adaptive, and scalable solutions that drive continuous improvement and operational agility.

FAQs: Industrial AI Solution Essentials

Is industrial AI compatible with legacy systems?

Yes, modern industrial AI software is generally designed to integrate with existing operational systems through standardized data connectors and contextualization tools. While legacy systems can benefit from AI integration, unlocking the full range of AI capabilities often requires some degree of platform modernization. CruxOCM offers a hybrid software solution that enhances adaptability with legacy infrastructure; however, a thorough assessment should be conducted on a case-by-case basis to determine the best integration approach.

Can AI be used for real-time operational decisions?

Absolutely. AI systems process data in real time, enabling immediate insights and automated adjustments for optimal process control.

What data is needed for industrial AI systems?

Industrial AI relies on data from sensors, control systems, equipment logs, and operational databases. The more contextualized and comprehensive the data, the better the AI’s performance.

How scalable are industrial AI solutions?

Industrial AI platforms are built for scalability, allowing organizations to start with targeted applications and expand across sites and functions as needed.

Can AI improve throughput in midstream operations?

Yes. AI-driven solutions like pipeBOT™ and maxOPT™ by CruxOCM have demonstrated measurable improvements in throughput, consistency, and operational reliability in midstream oil and gas.

What are the cost implications and ROI of deploying AI in midstream assets?

The cost of deploying AI in midstream assets includes investments in software, data integration, infrastructure upgrades, and workforce training. Key cost drivers are data preparation, cloud or on-premise infrastructure, hiring or upskilling technical talent, and ongoing system maintenance. While upfront costs can be significant, AI typically delivers strong ROI by reducing unplanned downtime, optimizing throughput, and extending asset lifespans, resulting in substantial OPEX savings. Automation also reduces manual labor and compliance costs. Companies that implement AI in midstream operations often see measurable improvements in operational efficiency, safety, and profitability, with ROI driven by fewer maintenance events, higher asset utilization, and improved risk management.

Conclusion

Industrial AI has advanced rapidly, fundamentally reshaping oil and gas operations and driving a new era of efficiency, safety, and profitability. By automating routine and complex processes, AI-powered solutions dramatically reduce manual workload and cognitive strain, empowering operators to focus on high-value decision-making. This synergy between advanced technology and human expertise not only fosters safer and more reliable operations but also delivers measurable business value.

As a leading provider of AI-powered industrial software solutions, CruxOCM is at the forefront of this transformation. Our comprehensive suite of tools enables midstream businesses to achieve operational autonomy, optimize processes, and amplify the capabilities of their workforce. Companies that embrace industrial AI solutions are best positioned to enhance efficiency, ensure compliance, and secure long-term competitiveness in the energy industry.